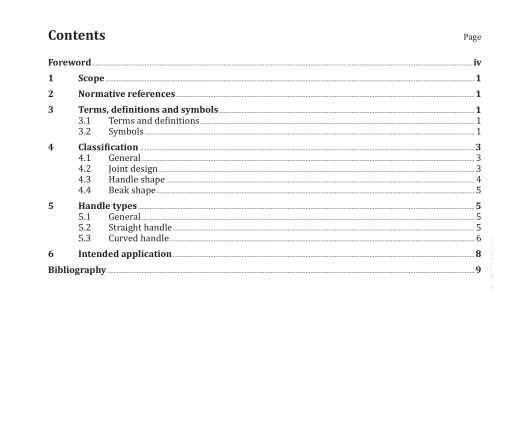

ISO 9173-3:2014 pdf download.Dentistry — Extraction forceps — Part 3: Design

This part of ISO 9173 specifies the design for extraction forceps used in dentistry.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1942, Dentistry — Vocabulary

ISO 9173-1, Dentistry — Extraction forceps — Part 1: General requirements and test methods

ISO 9173-2, Dentistry — Extraction forceps — Part 2: Designation

3 Terms, definitions and symbols

For the purposes of this document, the terms and definitions given in ISO 1942, ISO 9173-1, ISO 9173-2

and the following terms, definitions and symbols apply.

3.1 Terms and definitions

3.1.1 beak

<extraction forceps> functional working end of forceps which contacts the teeth

3.1.2 joint

<extraction forceps> connection point for first and second handles which are pivotally connected

3.1.3 handle

<extraction forceps> part which is held in the hand

3.2 Symbols

b 1 beak thickness

b 2 crown space width

b 3 beak separation

b 4 beak width (combined)

h 1 beak offset 1

h 2 beak offset 2

4.4 Beak shape

The beaks of extraction forceps are classified according to their inner areas into the following types:

a) — coated;

— non-coated,

b) — smooth;

— serrated.

The beaks are designed to fit around the cervical portion of the tooth, i.e. around the curve of the tooth’s

crown. Pointed beaks are designed to grip the furcation area.

Universal forceps have a beak that can be used in any quadrant of the mouth.

Extraction forceps designed for multi-rooted teeth have beaks with a point that is adapted to grip the tooth furcation.

l 1 overall forceps length

l 2 overall beak length

l 3 working length of beak

The dimensions are shown in Figure 1. The indication of measurement points with forceps closed is

presented in Table 1.

5Handle types

5.1 General

The shape of the handle is left to the discretion of the manufacturer.

The surface profile of the handle shall be designed according to the choice of the manufacturer. The knurled handle such as that shown in Figure 6 is given by way of example only. Other handle designs such as the one shown in Figure 8 (e.g. with indentations, anatomical) are also acceptable.

The surface of the handle shall be easy to clean.

The following handle designs are given as examples:

a) a knurled handle allows the operator to have a better grip.

b) a palm grasp is used with the handle of the extraction forceps.

c) a curve on the end of the handle can be present for the little finger, to provide more stability and leverage.

d) maxillary forceps have a handle which is often curved upwards, with the beak in line with the handle.

e) mandibular forceps have a straight handle with the beak at a 90° angle to the handle.

5.2 Straight handle

5.2.1 Straight handle Type 1

See Figure 6.

6 Intended application

The combination of the different designs for beak, joint and handle results in a specific extraction forceps with an intended application. The manufacturer shall indicate the intended application of the extraction forceps in accordance with ISO 9173-2. The usage of extraction forceps is subdivided into application for adults and for children (smaller forceps). A further design specification is the intended application to specific areas of the oral region or teeth as given in ISO 9173-2.ISO 9173-3 pdf download.ISO 9173-3 pdf download