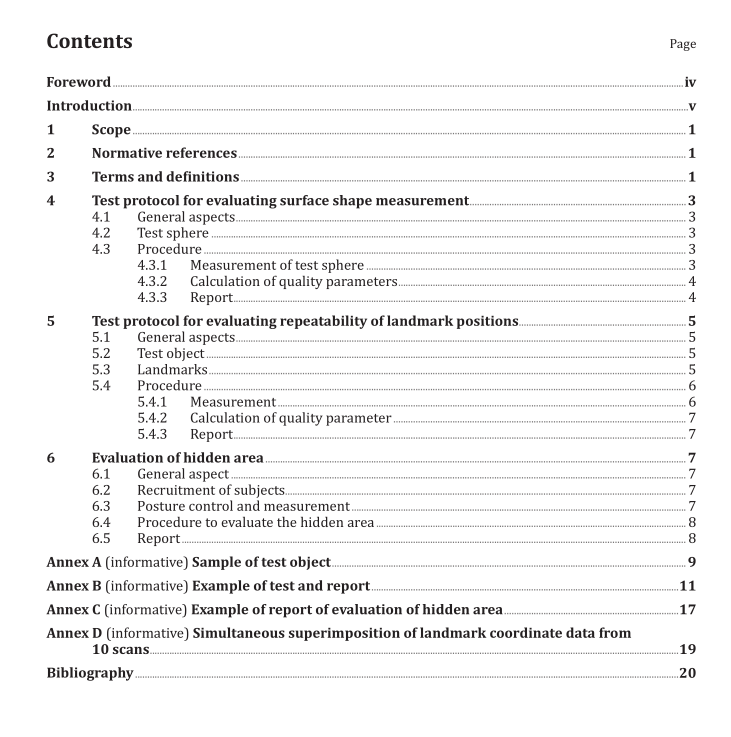

BS ISO 20685-2:2015 pdf download.Ergonomics — 3-D scanning methodologies for internationally compatible anthropometric databases Part 2: Evaluation protocol of surface shape and repeatability of relative landmark positions

This part of ISO 20685 addresses protocols for testing of 3-D surface-scanning systems in the acquisition of human body shape data and measurements. It does not apply to instruments that measure the motion of individual landmarks.

While mainly concerned with whole-body scanners, it is also applicable to body-segment scanners (head scanners, hand scanners, foot scanners). This International Standard applies to body scanners that measure the human body in a single view. When a hand-held scanner is evaluated, it has to be noted that the human operator can contribute to the overall error. When systems are evaluated in which the subject is rotated, movement artefacts can be introduced; these can also contribute to the overall error.

This part of ISO 20685 applies to the landmark positions determined by an anthropometrist. It does not apply to landmark positions automatically calculated by software from the point cloud. The quality of surface shape of the human body and landmark positions is influenced by performance of scanner systems and humans including measurers and subjects. This part of ISO 20685 addresses the performance of scanner systems by using artefacts rather than human subjects as test objects.

Traditional instruments are required to be accurate to millimetre. Their accuracy can be verified by comparing the instrument with a scale calibrated according to an international standard of length. To verify or specify the accuracy of body scanners, a calibrated test object with known form and size is used.

The intended audience is those who use 3-D body scanners to create 3-D anthropometric databases including 3-D landmark locations, the users of these data, and scanner designers and manufacturers. This part of ISO 20685 intends to provide the basis for the agreement on the performance of body scanners between scanner users and scanner providers as well as between 3-D anthropometric database providers and data users.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies

. ISO 7250-1, Basic human body measurements for technological design — Part 1: Body measurement definitions and landmarks

ISO 10360-8, Geometrical product specifications (GPS) — Acceptance and reverification tests for coordinate measuring systems (CMS) — Part 8: CMMs with optical distance sensors

ISO 20685, 3-D scanning methodologies for internationally compatible anthropometric databases

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 error of spherical form measurement

error within the range of the Gaussian radial distance, determined by a least-squares fit of measured data points on a test sphere

Note 1 to entry: Error of spherical form measurement is associated with the performance of the body scanner and the sphericity of the test sphere.

3.2 spherical form dispersion value

smallest width of a spherical shell that includes n % of all the measured data points

Note 1 to entry: See Figure 1, right.

Note 2 to entry: n should be 90 %.

3.3 standard deviation of radial distances

standard deviation of radial distances from measured data points and best-fit sphere

Note 1 to entry: Standard deviation of radial distances is an indicator of error of spherical form measurement and is highly correlated with error of spherical form measurement (90 %).

3.4 error of diameter measurement

error of the diameter of a least-squares fit of measured data points on a test sphere Note 1 to entry: See Figure 1, left.

Note 2 to entry: It is calculated as the measured diameter minus the calibrated diameter.

4 Test protocol for evaluating surface shape measurement

4.1 General aspects

The environmental conditions shall correspond to the operating conditions of the 3-D body scanner.

When operation mode needs to be modified to measure the test object, it shall be specified in the report.

4.2 Test sphere

Sphere made of steel, ceramic, or other suitable materials with diffusely reflecting surface are used to determine the quality parameter spherical form dispersion value and error of diameter measurement.

It is desirable that the diameter of the sphere should be larger than 10 % of the largest dimension of a rectangular parallelepiped scanning volume.BS ISO 20685-2 pdf download.BS ISO 20685-2 pdf download