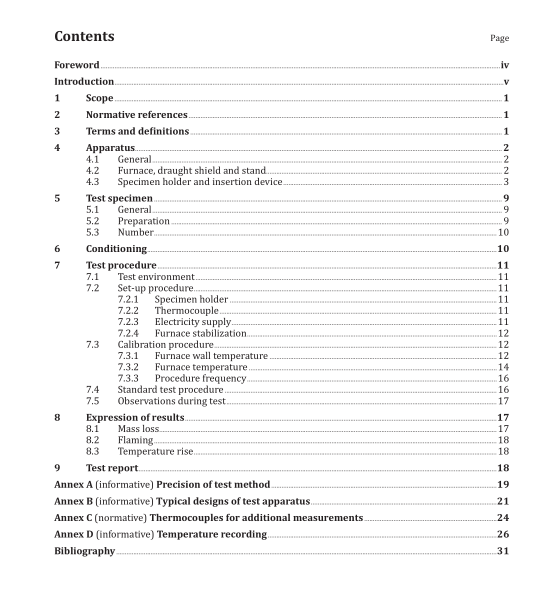

EN ISO 1182:2020 pdf download.Reaction to fire tests for products – Non-combustibility test (ISO 1182:2020)

4 Apparatus

4.1 General

The test apparatus shall be capable of creating the conditions specified in 7.1. A typical design of furnace is given in Annex B; other designs of furnace may be used.

NOTE 1 All dimensions given in the description of the test apparatus are nominal values, unless tolerances are specified.

The apparatus shall consist of a furnace comprising essentially a refractory tube surrounded by a heating coil and enclosed in an insulated surround. A cone-shaped airflow stabilizer shall be attached to the base of the furnace and a draught shield to its top.

The furnace shall be mounted on a stand and shall be equipped with a specimen holder and a device for inserting the specimen-holder into the furnace tube.

Thermocouples, as specified in 4.4, shall be provided for measuring the furnace temperatures and the furnace wall temperature. The thermal sensor, as specified in 4.5, shall be provided for measuring the furnace temperature along its central axis.

NOTE 2 Annex C gives details of additional thermocouples to be used if the specimen surface temperature and the specimen centre temperature are required.

4.2 Furnace, draught shield and stand

4.2.1 Furnace tube, made of an alumina refractory material as specified in Table 1, of density (2 800 ± 300) kg/m 3 . It shall be (150 ± 1) mm high with an internal diameter of (75 ± 1) mm and a wall thickness of (10 ± 1) mm.

The furnace tube shall be fitted in the centre of a surround made of insulating material 150 mm in height and of 10 mm wall thickness, and fitted with top and bottom plates recessed internally to locate the ends of the furnace tube. The annular space between the tubes shall be filled with a suitable insulating material.

NOTE 1 An example of a typical furnace tube design is given in B.2. An open-ended cone-shaped airflow stabilizer shall be attached to the underside of the furnace. The stabilizer shall be 500 mm in length, and reduce uniformly from 75 ± 1 mm internal diameter at the top to 10 ± 0,5 mm at the bottom.

The stabilizer shall be manufactured from 1 mm-thick sheet steel, with a smooth finish on the inside. The joint between the stabilizer and the furnace shall be a close, airtight fit, with a smooth finish internally.

The upper half of the stabilizer shall be insulated externally with a suitable insulating material.

NOTE 2 An example of suitable insulating material is given in B.3. 4.2.2 Draught shield, made of the same material as the stabilizer cone, and provided at the top of the furnace. It shall be 50 mm high and have an internal diameter of (75 ± 1) mm. The draught shield and its joint with the top of the furnace shall have a smooth finish internally, and the exterior shall be insulated with a suitable insulating material.

NOTE An example of suitable insulating material is given in B.4. 4.2.3 Stand, firm and horizontal, on which the assembly of the furnace, stabilizer cone and draught shield are mounted.

There shall be a base and draught screen attached to the stand to reduce draughts around the bottom of the stabilizer cone. The draught screen shall be 550 mm high and the bottom of the stabilizer cone shall be 250 mm above the base plate. 4.3 Specimen holder and insertion device 4.3.1 Specimen holder, as specified in Figure 1 and made of nickel/chromium or heat-resisting steel wire. A fine metal gauze tray of heat-resisting steel shall be placed in the bottom of the holder.

The mass of the holder shall be (15 ± 2) g. Due to ageing, specimen holders can lose weight. The mass of the holder shall be regularly checked.

The specimen holder shall be capable of being suspended from the lower end of a tube of stainless steel having an outside diameter of 6 mm and a bore of 4 mm.EN ISO 1182 pdf download.EN ISO 1182:2020 pdf download