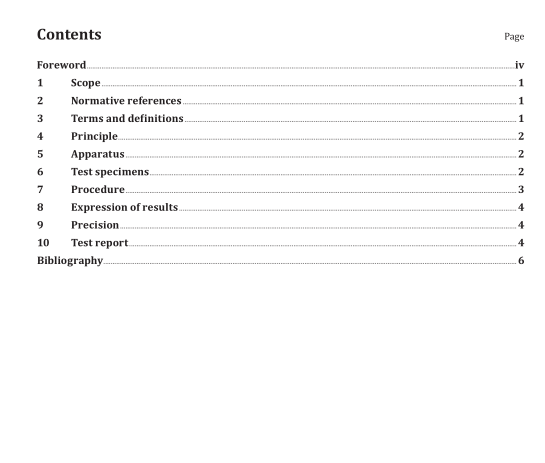

ISO 11339:2022 pdf download.Adhesives — T-peel test for flexible-to- flexible bonded assemblies

This document specifies a T-peel test for the determination of the peel resistance of an adhesive by measuring the peeling force of a T-shaped bonded assembly of two flexible adherends. This test procedure does not provide design information.

NOTE This method was originally developed for use with metal adherends but other, flexible, adherends can also be used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 10365, Adhesives — Designation of main failure patterns

ISO 17212, Structural adhesives — Guidelines for the surface preparation of metals and plastics prior to adhesive bonding

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 peel resistance

force per unit width necessary to bring an adhesive joint to the point of failure or to maintain a rate of failure by means of a stress applied in the peeling mode

Note 1 to entry: The peel resistance can be expressed as force per unit peel width.

[SOURCE: ISO 472:2013, 2.683, modified — “peel strength” is replaced by “peel resistance” in the Note.]

4 Principle

For the T-peel test for a flexible-to-flexible assembly, the force is applied to the unbonded ends of the specimen. The angle between the bond line and the direction of the applied force is not fixed. Adherends are separated at an approximately steady rate from an open edge of a prepared bond so that separation occurs progressively along the bond line.

5 Apparatus

5.1 Tensile-testing machine 1) , capable of maintaining a predetermined constant crosshead rate (preferred rate 100 mm/min). It shall be provided with a suitable self-aligning grip to hold the specimen. Each set of jaws of the grip shall firmly engage the outer 25 mm of the unbonded ends of the flexible adherends. The grip and attachments shall be constructed in such a way that they will move into alignment with the specimen as soon as the force is applied. The machine shall produce a chart that can be read in terms of millimetres of crosshead movement as a function of the applied force. The machine shall permit the measurement and recording of the applied force with an accuracy of ±2 %. All equipment shall be calibrated regularly. It is recommended that a clamping device with low inertia be used.

5.2 Device for measuring thickness, with an accuracy of ±0,01 mm, or a means of checking the thickness to that tolerance.

6 Test specimens

6.1 Test specimens of the dimensions shown in Figure 1 shall be prepared, either individually or cut from bonded laminates. Test specimens shall consist of two flexible adherends properly prepared and bonded together.

6.2 Surface treatment shall be such as to obtain optimum strength in the bonded assembly.

The preparation of the surface shall be in accordance with ISO 17212, and details of the preparation shall be stated in the test report. The adhesive shall be applied in accordance with the manufacturer’s instructions to obtain an optimum bond with minimum variation; the procedure used shall be reported in the test report. NOTE Direct comparison of different adhesives can be made only when specimen construction, adherend materials and dimensions, and test conditions are identical.

6.3 The thickness of the flexible adherends shall be reported.

The preferred thicknesses are 0,5 mm ± 0,02 mm for steel (type XES) 2) and 0,7 mm ± 0,02 mm or 0,5 mm ± 0,02 mm for aluminium (type 5754, H111) 3) unless otherwise specified.ISO 11339 pdf download.ISO 11339 pdf download