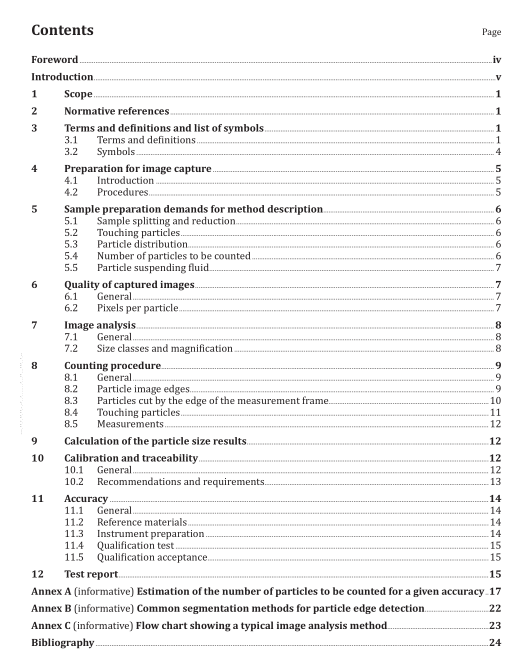

ISO 13322-1:2014 pdf download.Particle size analysis — Image analysis methods — Part 1: Static image analysis methods

4 Preparation for image capture

4.1 Introduction A pre-requisite for accurate particle size measurement using this method requires a full understanding of the settings and calibration applied within the image capture device as well as a consideration of the purpose for conducting the measurement. The final settings and calibration of the image capture device need to be established via an iterative approach. The size range of the particles within an unknown test sample has an influence upon the settings required within the image capturing device.

These remain unknown until the first image has been taken, the result observed and the necessary adjustments to the image capture device to achieve the desired accuracy of particle size measurement required. A fully trained operator shall conduct the assessment.

The imaging instrument should be set up and operated in accordance with the manufacturer’s recommendations considering the conditions prevailing. In order to achieve accurate particle size measurements it is preferred that the illumination be uniform over the total field of view and of a type designed to create images of high contrast. The magnification should be such as to provide a minimum number of pixels for the smallest particle consistent with the accuracy demanded and set to achieve a sharp focus.

The number of pixels for the smallest dimension of a particle is relevant for cases where linear dimensions or combinations thereof are measured. Distortion in the image might arise from a number of causes, but its presence and effect on the image may be determined by selecting known sized particles or other reference objects of similar optical properties at a number of points and orientations in the field of view. It is important to note that the measurements made provide only two-dimensional, X and Y, information.

4.2 Procedures The operator should decide why the result of the image analysis is required. Is a size distribution by the number of particles in each size class required or is the volume of particles in each size class the requirement What accuracy and precision is required for the final result? These decisions will have a significant influence upon the choice of settings and the method employed in conducting the measurement. For each material to be analysed and for each instrument employed the person conducting the analysis shall ensure that the following procedures are followed.

a) Ensure an adequate calibration for both the X and Y-axis of the measurement frame exists for the imaging instrument being employed, preferably by using a certified graticule or equivalent reference of equal standing.

b) Ensure that the optical magnification employed is suitable and such as the image of the smallest particle to be measured covers a sufficient number of pixels to support the required accuracy of measurement.

c) Ensure that the illumination method and setting of any focus is correctly established to give a good contrast and uniformity of illumination of any image gathered.

d) Ensure that the number of particles within the measurement frame is such as to minimize the number of touching particles.

e) Ensure that a sufficient number of images of separate aliquot samples are gathered to provide a suitable total number of particles with respect to the type of distribution, number or volume based, and the width of the particle size distribution (see ISO 14488) and that they contain an adequate statistical number of the largest particle of the target material (see Annex A).

f) Some implementations of the image analysis technique employ a large area X, Y servo or manually controlled sample slide assembly. Such large slides enable many measurement frames of the particles deposited to be examined. Should the method of fully separate measurement frames be employed then any frame overlap shall be avoided. If the method of overlapping measurement frames, or other methods of analysing particles that interact with the measurement frame edge is used, then procedures shall be employed to ensure that each particle is only included into the total count for the appropriate size class, once. For more information, see 8.3.ISO 13322-1 pdf download.ISO 13322-1 pdf download