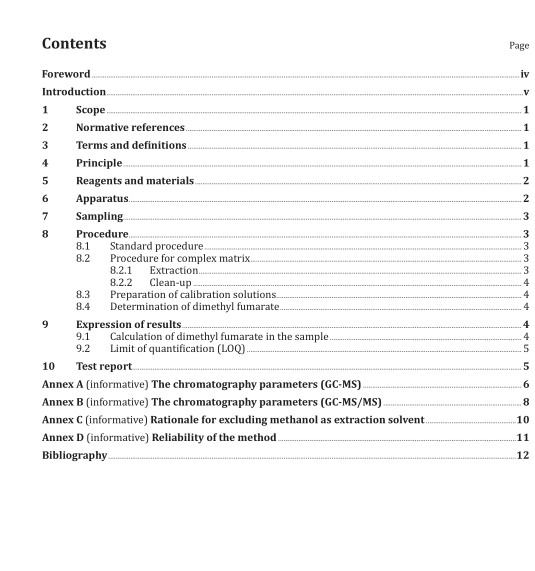

ISO 16186:2021 pdf download.Footwear — Critical substances potentially present in footwear and footwear components — Determination of dimethyl fumarate (DMFU)

This document specifies a method for the determination of the content of dimethyl fumarate (DMFU) by gas chromatograph with single quadrupole mass spectrometer (GC-MS) or tandem quadrupole mass spectrometer (GC-MS/MS).

This document is applicable to all types of footwear and footwear components except metal parts.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4787, Laboratory glassware — Volumetric instruments — Methods for testing of capacity and for use 3? Terms? and? definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

4 Principle

The sample is extracted using acetone (see precaution for the solvent in Annex C) at 60 °C in an ultrasonic bath. At this step, two different procedures can be used, depending on the material being tested:

a) The “standard procedure,” without purification and concentration of the extracted solution, can be used for samples giving a simple chromatogram, for example, textile footwear components.

b) The “procedure for complex matrix”, with purification and concentration of the extract, can be used for samples with a complex matrix effect, such as leather.

An aliquot of the extract is analysed using a gas chromatography with single quadrupole mass spectrometry (GC-MS) or tandem quadrupole mass spectrometry (GC-MS/MS).

6.6? Volumetric? flasks

6.7 Gas chromatograph with mass selective detector (GC-MS or GC-MS/MS).

6.8 Amber glass vial, with screw cap that can be tightly sealed (e.g. volume of 10 ml).

6.9 Activated magnesium silicate cartridge.

NOTE The two following cartridges have been found suitable.

a) Pre-packed cartridge of FL-PR Florisil® 2) (170 µm, 80 Å) 2 g/12 ml.

b) Bulk material of Florisil® 100-200 mesh, fine powder.

6.10 Nitrogen evaporator, with conical tubes and with adjustable temperature, suitable for operation up to 40 °C.

7 Sampling

The test specimen shall consist of a single material type (made of textile, leather, polymer or other organic material), which is tested separately.

Cut the homogenous material samples into pieces of about 3 mm to 5 mm edge length.

NOTE 1 Up to three test specimens (of equal mass) of the same material type can be tested together, taking into consideration the limits of detection and quantification.

NOTE 2 Desiccant can be a source of DMFU contamination of the footwear. Desiccant samples can be used without any processing.

8 Procedure

8.1 Standard procedure

Weigh (1,0 ± 0,1) g of the sample in a glass vial (6.2), record the mass to the nearest 1 mg, add 0,1 ml of the solution of internal standard working solution (5.6.2) and 9,9 ml of acetone (5.1), and seal the vial.

Extract the sample at (60 ± 5) °C for (60 ± 5) min in an ultrasonic bath (6.3).

WARNING — Do not open the vial before cooling as the content can be under pressure.

After cooling to below at least 27 °C, decant the solution and, if necessary, reduce to 1,0 ml under a gentle stream of nitrogen (6.10).

Filter this solution through a PTFE membrane filter (6.4).

Transfer an aliquot of the extract to a GC vial (6.5) and seal with a cap.

8.2 Procedure for complex matrix

8.2.1 Extraction

Weigh (1,0 ± 0,1) g of the sample in a glass vial (6.2), record the mass to the nearest 1 mg, add 0,1 ml of the solution of internal standard (5.6.2) and 9,9 ml of acetone (5.1), and seal the vial. Extract the sample at (60 ± 5) °C for (60 ± 5) min in an ultrasonic bath (6.3).

8.2.2 Clean-up

After cooling to below at least 27 °C, transfer 5 ml of the extract to a conical tube and reduce to around 0,2 ml under a gentle stream of nitrogen (6.10).ISO 16186 pdf download.