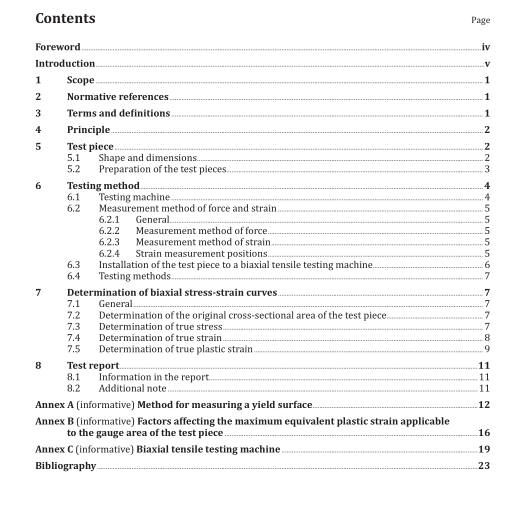

ISO 16842:2021 pdf download.Metallic materials — Sheet and strip — Biaxial tensile testing method using a cruciform test piece.

4 Principle

Measurement is made at room temperature on the yield stress and the stress-strain curves of sheet metals under biaxial tensile stresses by measuring simultaneously and continuously the biaxial tensile forces and strain components applied to the gauge area of a cruciform test piece while applying biaxial tensile forces in the orthogonal directions parallel to the arms of the test piece. The test piece is made of a flat sheet metal and has a uniform thickness.

The measured biaxial stress-strain curves are used to determine contours of plastic work of the sheet samples (see Annex A).

According to the finite element analyses of the cruciform test piece (as recommended in Clause 5) and the strain measurement position (as specified in 6.2.4), the stress calculation error is estimated to be less than 2,0 % [2][3] .

5 Test piece

5.1 Shape and dimensions Figure 1 shows the shape and dimensions of the cruciform test piece recommended in document.

The test piece shall be as described as follows:

a) In principle, the thickness of a test piece, a, shall be the same as that of the as-received sheet sample, without any work done in the thickness direction. See 5.1 b) for an exception to the rule.

b) The arm width, B, should be 30 mm or more, except where it is determined according to the agreement between parties involved in transaction. It shall satisfy a ≤ 0,08B and should be accurate to within ±0,1 mm for all four arms.

The sheet thickness can be reduced to satisfy a ≤ 0,08B according to the agreement between the parties involved in transaction.

c) Seven slits per one arm shall be made. Specifically, one slit shall be made on the centreline (x-axis or y-axis) of the test piece with a positional accuracy of ±0,1 mm, and three slits shall be made at an interval of B/8 with a positional accuracy of ±0,1 mm on each side of the centreline. All slits shall have the same length, L, and should be accurate to within ±0,1 mm. The relationship of B ≤ L ≤ 2B should be established. The opposing slit ends shall be made at an equal distance, B Sx /2 and B Sy /2, from the centreline with a positional accuracy of B/2 ± 0,1 mm.

d) The slit width, w S , should be made as small as possible (see Figure B.2), preferably less than 0,3 mm.

e) The grip length, C, is considered to be sufficient if it can secure the test piece to the grips of the biaxial tensile testing machine and can transmit the necessary tensile force to the test piece. The standard grip length would be B/2 ≤ C ≤ B, but it can be determined arbitrarily according to the agreement between the parties involved in the transaction.

f) An alternative test piece geometry can be used. In the use of the alternative cruciform test pieces,the evidence of the stress measurement accuracy shall be clarified between the contractual partners.

5.2 Preparation of the test pieces

a) The permitted variations in thickness and the permitted variations from a flat surface of the sheet metal sample from which the cruciform test pieces are taken shall be in accordance with relevant product standards or national standards.

b) The standard sampling direction of the test piece shall be such that the directions of arms are parallel to the rolling (x) and transverse (y) directions of the sheet sample, respectively. The test piece sampling direction can be determined according to the agreement between parties involved in transaction.

c) For the fabrication of the test piece (including making of slits), any method, e.g. laser cutting, water jet cutting, or other alternative manufacturing methods, demonstrated to work satisfactorily can be used if agreed upon by the parties.

d) Unless otherwise specified and except for the sampling work, unnecessary deformation or heating to the test piece shall be avoided.ISO 16842 pdf download.ISO 16842 pdf download