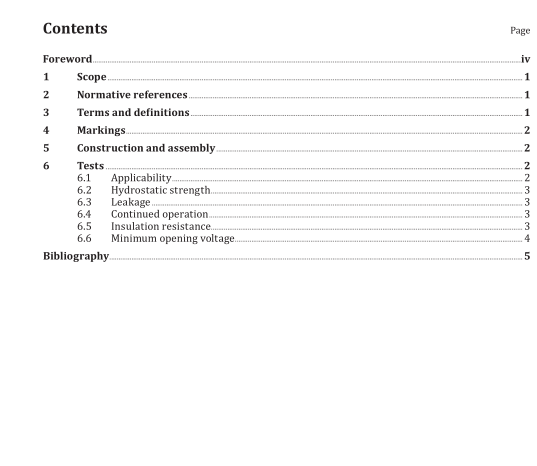

ISO 20766-16:2022 pdf download.Road vehicles — Liquefied petroleum gas (LPG) fuel system components — Part 16: Injectors and gas mixing device/fuel rail

This document specifies general requirements for the injectors and gas mixing device/fuel rail,components of liquefied petroleum gas fuel, intended for use on the types of motor vehicles as defined in ISO 3833. It also provides general design principles and specifies requirements for instructions and marking.

This document is applicable to vehicles (mono-fuel, bi-fuel or dual-fuel applications) using gaseous fuels in accordance with ISO 9162. It is not applicable to the following:

a) fuel containers;

b) stationary gas engines;

c) container mounting hardware;

d) electronic fuel management;

e) refuelling receptacles.

It is recognized that miscellaneous components not specifically addressed herein can be examined for compliance with the criteria of any applicable part of the ISO 20766 series, including testing to the appropriate functional tests.

All references to pressure in this document are considered gauge pressures unless otherwise specified.

This document applies to devices which have a service pressure in the range of 110 kPa (butane rich at 20 °C) and 840 kPa (propane at 20 °C), hereinafter referred to in this document. Other service pressures can be accommodated by adjusting the pressure by the appropriate factor (ratio).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 20766-1, Road vehicles — Liquefied petroleum gas (LPG) fuel systems components — Part 1: General requirements and definitions

ISO 20766-2:2018, Road vehicles — Liquefied petroleum gas (LPG) fuel systems components — Part 2:Performance and general test methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 20766-1 apply.

6.2 Hydrostatic strength

Test the injectors and gas mixing device/fuel rail according to the procedure for testing hydrostatic strength specified in ISO 20766-2. The test pressure shall be 2,25 times the working pressure.

6.3 Leakage

Test the injectors and gas mixing device/fuel rail at the temperatures and pressures given in Table 2.

6.4 Continued operation

Subject the gas injector or fuel rail assembly to 600 × 10 6 pulses at working pressure and room temperature. This procedure may be interrupted at 20 % intervals in order to check test criteria.

The minimum frequency for the pulses shall be 50 Hz.

Upon completion of this test, the gas injector or fuel rail assembly shall pass the leakage test in accordance with ISO 20766-2:2018, Clause 6, and the insulation resistance test given in 6.4.

6.5 Insulation resistance

This test is designed for checking the insulation resistance between the connector pin and the housing.

Apply a test voltage of 500 V d.c. for a duration of 60 s; for injectors with circuitry of 3,8 mm pitch or below, 100 V d.c. shall be used

The minimum allowable resistance shall be >10 MΩ.

6.6 Minimum opening voltage

The minimum opening voltage at room temperature shall be ≤8 V for a 12 V system and ≤16 V for a 24 V system. The component shall be pressurized at 0,75 times the working pressure during the test.ISO 20766-16 pdf download.ISO 20766-16 pdf download