ISO 20766-24:2022 pdf download.Road vehicles — Liquefied petroleum gas (LPG) fuel system components — Part 24: Gas tubes.

This document specifies general requirements and definitions for the gas tube component of liquefied petroleum gas fuel, intended for use on the types of motor vehicles as defined in ISO 3833. It also provides general design principles and specifies requirements for instructions and marking.

This document is applicable to vehicles (mono-fuel, bi-fuel or dual-fuel applications) using gaseous fuels in accordance with ISO 9162. It is not applicable to the following:

a) fuel containers;

b) stationary gas engines;

c) container mounting hardware;

d) electronic fuel management;

e) refuelling receptacles.

It is recognized that miscellaneous components not specifically addressed herein can be examined for compliance with the criteria of any applicable part of the ISO 20766 series, including testing to the

appropriate functional tests.

All references to pressure in this document are considered gauge pressures unless otherwise specified.

This document applies to devices which have a service pressure in the range of 110 kPa (butane rich at 20 °C) and 840 kPa (propane at 20 °C), hereinafter referred to in this document. Other service pressures can be accommodated by adjusting the pressure by the appropriate factor (ratio).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 20766-1, Road vehicles — Liquefied petroleum gas (LPG) fuel systems components — Part 1: General requirements and definitions

ISO 20766-2, Road vehicles — Liquefied petroleum gas (LPG) fuel systems components — Part 2: Performance and general test methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 20766-1 and the following apply.

Specific care shall be taken against galvanic corrosion.

Gas tubes and couplings should mate to avoid galvanic corrosion.

Only straight longitudinal welding (in the direction of the tube itself) is permitted in gas tubes of nonseamless type.

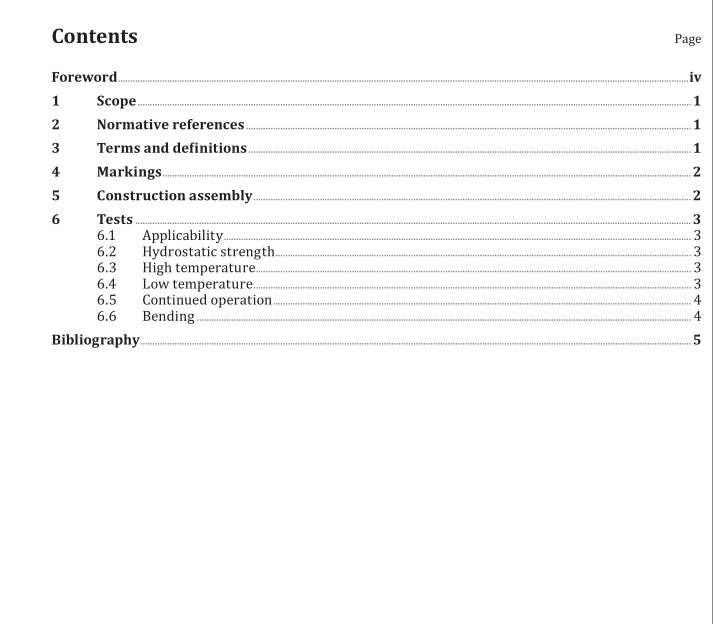

6 Tests

6.1 Applicability

The tests required to be carried out are indicated in Table 1.

6.2 Hydrostatic strength

Test the gas tubes according to the procedure for testing hydrostatic strength specified in ISO 20766-2.

The test pressure shall be 2,25 times the working pressure.

6.3 High temperature

The gas tubes shall not leak more than 15 cm 3 /hour (normal) at a room temperature of 20 °C ± 5 °C when subjected to leakage test specified in ISO 20766-2 at the maximum operating temperature

(65 °C or 85 °C or 120 °C as applicable) and with the pressure equal to 150 % of working pressure. The component shall be conditioned for at least 8 h at this temperature.

6.4 Low temperature

The gas tubes shall not leak more than 15 cm 3 /hour (normal) at a room temperature of 20 °C ± 5 °C when subjected to leakage test specified in ISO 20766-2 at the minimum operating temperature (-40 °C

or -20 °C as applicable) and with the pressure equal to 150 % of working pressure. The component shall be conditioned for at least 8 h at this temperature.

6.5 Continued operation

Test the gas tubes in accordance with the procedure for testing continued operation given in ISO 20766-2 for a total of 100 000 cycles.

6.6 Bending

Test the gas tubes according to the following procedure and acceptance criterion.

a) Select a mandrel with an external diameter according to Table 2.

b) Bend the gas tubes over this mandrel once, forming a “U” shape.

c) Close the ends of the gas tubes and subject it to the hydrostatic test of 6.2. of this document. At the completion of the hydrostatic test, the gas tubes shall be tested according to the procedure for leakage testing specified in ISO 20766-2.ISO 20766-24 pdf download.