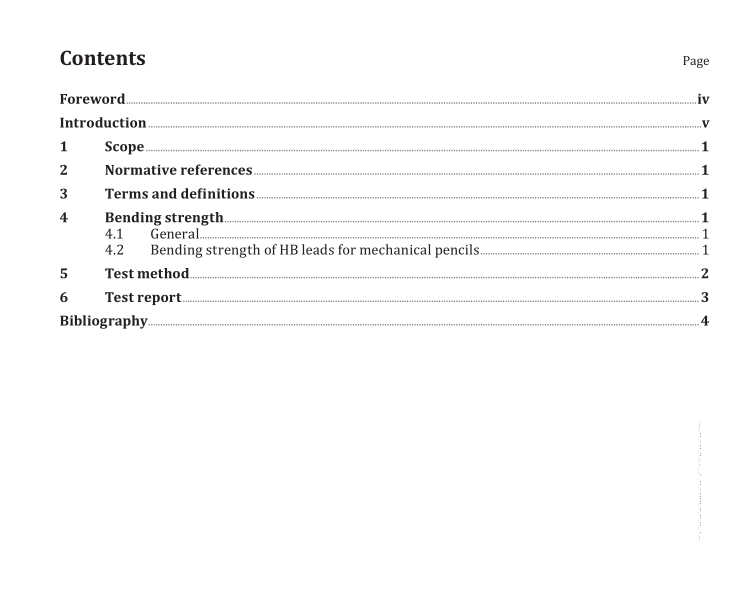

ISO 9177-3:2022 pdf download.Mechanical pencils for technical drawings — Part 3: Black leads — Bending strengths of HB leads

This document specifies bending strengths and a test method for black leads of HB hardness degree used for mechanical pencils for technical drawings.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 bending strength

quality requirement of lead strength as determined by bending the lead to its breaking point, using a prescribed test method and formula

4 Bending strength

4.1 General

Bending strength of HB leads used for mechanical pencils shall be tested in accordance with Clause 5 and shall satisfy the requirements specified in 4.2.

4.2 Bending strength of HB leads for mechanical pencils

The bending strength (σ) shall be not less than the value specified in Table 1 corresponding to the respective nominal diameter.

5 Test method

On a lead sample taken at random, bending strength shall be tested as follows:

Arrange the lead test piece as shown in Figures 1 and 2 and apply a load on the lead at a distance halfway between the two supporting anvils at the following rates (±10 %):

0,5 N/s for 2 mm nominal diameter lead;

0,l N/s for 0,35 mm, 0,5 mm, 0,7 mm and 1 mm nominal diameter leads.

These loading rates shall be verified beforehand using a rigid test piece instead of a lead.

Determine the load (F) at which the lead has broken and use this value to calculate the bending strength

(σ) according to the following formula:

where

σ is the bending strength, in megapascals;

F is the load, in newtons;

l is the distance, in millimetres, between the two supporting anvils according to Table 2;

d is the actual diameter of the lead, in millimetres.

6 Test report

The test report shall contain the following information:

a) reference to this document;

b) lead type (P or C);

c) actual diameter (relating to the nominal diameter) of the lead under test;

d) test values for F and l;

e) bending strength as evaluated according to Clause 5;

f) name of test centre, date and signature of person carrying out the test.ISO 9177-3 pdf download.ISO 9177-3-2022 pdf download