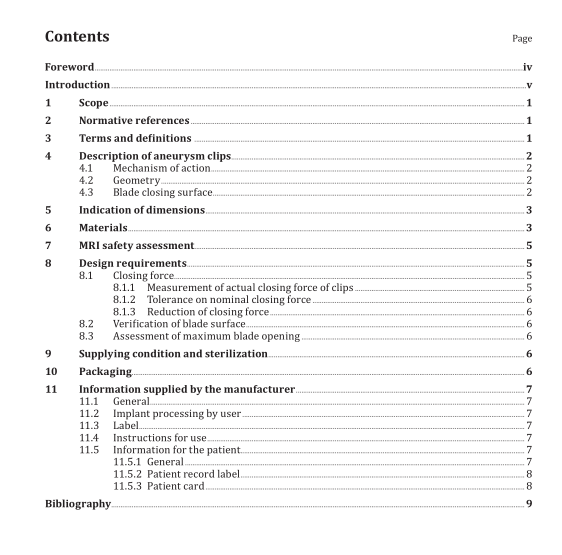

ISO 9713:2022 pdf download.Neurosurgical implants – Self-closing intracranial aneurysm clips.

4 Description of aneurysm clips

4.1 Mechanism of action

The mechanism of action for the clip shall be specified.

The illustrations of examples of clip mechanisms of action are shown in Figure 1.

4.2 Geometry

The geometry of the clip, including the blade geometry shall be specified.

The diagrammatic representation (not to scale) of some examples of clip forms is indicated in Figure 2.

4.3 Blade closing surface

The shape and geometric characteristics of the blade closing surface shall be described.

5 Indication of dimensions

The following dimensions of clips and components shall be indicated:

a) the overall length;

b) the length of the blades;

c) the width of the blades giving, as appropriate, the width (disregarding any radius or taper at the tip) of blades of uniform width, the minimum and maximum widths of non-uniform blades, and the overall width of fenestrated blades;

d) the internal diameter of any encircling or encompassing portions of the clip.

The variety of designs of clip does not make it feasible to specify the points between which the blade length should be measured. Manufacturers should indicate these points clearly on all diagrams.

Examples of indication of dimensions are given in Figure 3. The diagrams are for illustration only and do not indicate a definitive requirement.

It is suggested that the blade length be indicated as that portion of the jaw which comes into contact with the other jaw when the clip is closed without a vessel in place or, for encircling clips, the longitudinal internal dimension of the clip when closed.

6 Materials

The materials shall comply with the requirements of ISO 5832-2, ISO 5832-3, ISO 5832-5, ISO 5832-6 or ISO 5832-7.

Stainless steel is excluded as a material for aneurysm clips.

7 MRI safety assessment

In order to determine the conditions for which clips may be imaged using MR, performance tests for measuring the magnetic properties of finished implant is required.

NOTE 1 Investigation of the magnetic properties of the base material from which the clip is constructed is not sufficient to assess the MRI compatibility of the finished implant.

The worst-case clip for each evaluation shall be identified, noting that the worst case can be different for each test.

Testing and analyses shall be performed on the identified worst-case clip to determine magnetically induced forces, moments and heating, and to determine the image artefact produced by the clip under worst-case MR scanning conditions.

NOTE 2 Testing for determining magnetic properties of implants are available in ASTM F2052 [3] (induced displacement force), ASTM F2213 [4] (induced torque) and ASTM F2182 [5] (radio frequency induced heating), and ASTM F2119 [6] (artefact images).

The worst-case scanning conditions shall be informed in the labelling as indicated in Clause 11.

The resulting analyses concerning the MRI safety condition (safe, conditional or unsafe) shall be properly identified in the implant label by using appropriated graphical symbols.

NOTE 3 Information regarding the definition, the requirements for assessment and the labelling of different MRI safety conditions, including appropriate label icons, can be found in ASTM F2503 [2] and IEC 62570 [1] .

For MRI conditional implants, the applicable information to ensure the scanning safe condition shall be established. Conditions for scanning shall include magnetic field strength(s), maximum spatial field gradient, acceptable specific absorption rate (SAR) and extent of expected image artefact for a specific scan sequence.

8 Design requirements

8.1 Closing force

8.1.1 Measurement of actual closing force of clips

8.1.1.1 Apparatus

The apparatus shall be calibrated and capable of measuring the closing force of the clip, having a limit of error of 5 %.

NOTE 1 Limit of error of 5 % allows for the difference to be +5 % or –5 %.

NOTE 2 Several apparatus designs exist. No single design has been specified, as this is unduly restrictive.ISO 9713 pdf download.ISO 9713 pdf download